Target reader for this article: B2B buyers / distributors / rental companies / importers who are looking to buy 2 ton mini excavators from China, either to resell under their own brand or to build a rental fleet.

Imagine a typical buyer:

- 50+ years old, runs a construction equipment dealership in Europe or North America

- Knows sales very well, but not every technical detail inside a hydraulic system

- Has been burned before by: fake certificates, poor communication, and shipment delays

The questions below come up again and again in emails, video calls and trade fairs.

This article puts them all in one place, with straightforward, factory-floor type answers.

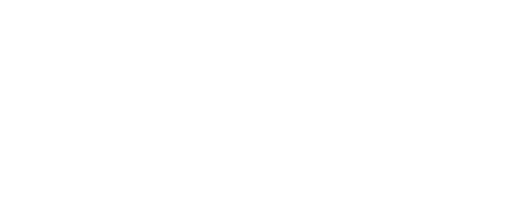

1. What can a 2 ton China mini excavator really do?

Many new buyers worry that a “2 ton” machine from China is only a toy.

Some sellers over-promise, some buyers over-expect. Better to keep it real.

Typical jobs for a 2 ton mini excavator

A well-built 2 ton mini excavator is ideal for:

- Garden and landscaping work

- Digging small ponds

- Shaping flowerbeds, small terracing

- Tree planting and removal (with the right attachment)

- Utility and light construction

- Trenching for cables, water pipes, drainage

- Small foundation work, footings for fences

- Interior demolition in tight spaces (with hammer)

- Farm work

- Cleaning ditches

- Small barn foundation repairs

- Loading light material into trailers (with a narrow bucket or grab)

What a 2 ton machine should not be expected to do

- Break heavy reinforced concrete slabs all day

- Work continuously in large rock quarries

- Handle oversized hydraulic hammers meant for 5–6 ton machines

- Load 20-ton dump trucks on big construction sites

In simple terms:

A 2 ton China mini excavator is a compact, versatile tool, not a full-size crawler excavator.

Why this matters for importers

Distributors and rental companies often try to cover too many jobs with one machine size.

If end users try to work a 2 ton excavator like a 6 ton machine, complaints will follow:

- “The boom feels weak”

- “The structure cracked”

- “The pump is noisy”

Most of these issues come from mis-matching job to machine, not just from poor quality.

A serious factory (for example, Nicosail) usually gives clear working range data and honest suggestions about:

- Maximum recommended hammer size

- Maximum trench depth

- Typical duty cycle per day

This helps importers set correct expectations for local customers and reduce after-sales headaches.

2. How does the quality compare to big brands?

This is the first big worry:

“If the price is much lower than a big brand, is the quality automatically bad?”

Reality is more nuanced.

Where Chinese 2 ton excavators are usually weaker

- Finishing and branding

- Paint may not look as “luxury” as big brands

- Wiring harness routing sometimes not as neat

- Plastics and cabin interior trim can feel more basic

- Long-term durability in extreme, high-duty usage

- 24/7 rental fleets on harsh construction sites

- Heavy hammering in rock with inexperienced operators

Big global brands spend huge budgets on R&D, testing and global support.

Chinese factories simply cannot match that at the same price level.

Where quality can actually be surprisingly good

A good Chinese factory can be strong in:

- Structural strength

- Properly sized steel sections on boom, arm and chassis

- Controlled welding procedure (WPS), not “random welders”

- Ultrasonic or magnetic test on critical welds, at least by sampling

- Hydraulic performance

- Stable swing, smooth boom/arm/bucket motions

- Reasonable working speed, no crazy jerkiness

- Leakage control – both hard pipes and soft hoses laid out with clamps and protection

- Engine and key components

- Use of mainstream engine brands (Kubota / Yanmar / Perkins / well-known Chinese brands)

- Use of recognized hydraulic brands for pumps and motors

Factories such as Nicosail, which run multiple production lines for mini excavators and loaders, generally standardize their:

- Welding process

- Painting process (pre-treatment, primer, topcoat)

- End-of-line (EOL) functional testing

This kind of standardization is what moves a machine from “cheap and risky” to “cost-effective and reliable for normal use”.

How importers can judge real quality without being experts

Here are some simple checks any buyer can ask for:

- Clear photos or videos of:

- Weld seams on boom base, arm root, undercarriage, and blade

- Hydraulic hose layout – are hoses tied, protected, or hanging loose?

- Cylinder rods – chrome quality, dust seals tidy or messy?

- Ask for a test video:

- Engine cold start

- All functions operated continuously for at least 20–30 minutes

- No obvious jerking, no abnormal noise, no visible leaks

- Ask for the factory’s standard inspection checklist for mini excavators

A factory that can provide these materials easily is usually more serious about quality.

3. Are the CE / EPA / other certificates real and acceptable for customs?

For European and North American importers, certificates are not a “nice to have”.

They are entry tickets. No ticket, no customs clearance.

Common certificates for 2 ton China mini excavators

- CE for European Union

- EPA (Tier 4) for the USA

- Sometimes UKCA for UK, depending on local rules

- ISO9001 for the factory’s quality management system (more of a background document)

Real problems many buyers have faced

- Fake CE: a simple self-made “CE” declaration without any real technical file

- Wrong engine emission level: engine plate says “EPA” but not the correct Tier level

- Certificate for a different model: documents for one model, used to sell a different one

- Expired or withdrawn certificates

These issues can cause:

- Containers stuck at customs

- Fines or forced re-export

- Damage to the importer’s local reputation

How to verify certificates in a simple way

- Match model names exactly

- The model on the machine plate, data plate, and manuals should match the certificate

- Watch out for small differences like “XN20” vs “XN2.0”

- Engine documents

- Ask for the engine emission certificate and make sure it matches the actual engine brand and model

- Check that the engine’s label matches the documents (the seller can send clear photos)

- Ask for sample documents in advance

- CE Declaration of Conformity

- EPA Certificate scan

- Test report (if available)

- Look at how the supplier reacts

- A serious supplier (like Nicosail and other well-organized factories) typically sends a full document pack:

- CE declaration

- Operation & maintenance manual

- Parts book

- Engine documents

- A risky supplier may only send a one-page CE “certificate” with obvious template styling and no real test information.

- A serious supplier (like Nicosail and other well-organized factories) typically sends a full document pack:

When in doubt, it is cheaper to reject a questionable supplier early than to deal with a container stuck in customs later.

4. How much should a 2 ton mini excavator from China cost?

Price is always sensitive. New buyers worry both about:

- Overpaying compared to other importers

- Going too cheap and getting poor quality or trouble with customs

What drives the price of a 2 ton China mini excavator

- Engine choice

- Top international brands (Kubota / Yanmar / Perkins): higher price

- Good local Chinese engines: lower price

- EPA / Stage V compliant versions: more expensive than non-compliant

- Hydraulic system

- Branded pump and motors vs unknown brands

- Extra auxiliary lines (e.g., double hydraulic circuits for hammer + auger)

- Cabin / canopy and options

- Open canopy vs closed cabin with heater / AC

- Suspension seat, LED work lights, extra counterweight

- Attachments included

- Standard bucket only

- Plus narrow trenching bucket

- Plus ripper, hydraulic thumb, auger, quick hitch, etc.

- Order quantity

- One or two units (sample order)

- Full container order

Typical price logic (not exact numbers, but relationships)

- 2 ton mini excavator

- Chinese engine + basic hydraulics: lowest price level

- Japanese / European engine + branded hydraulics: mid–high price

- Full options + branded components: highest price level

If one supplier offers a price far below the general range of other serious factories for the same spec, something is usually missing:

- Certificates

- Material thickness

- Component brands

- After-sales support

Why some buyers choose mid-range, not the lowest price

Importers who rebrand and sell at a premium (especially in Europe, Canada, Australia) prefer a stable mid-range cost machine that:

- Has reliable certificates

- Does not cause frequent warranty claims

- Protects their brand reputation

Factories like Nicosail, which aim at Europe, North America and Australia, usually position their 2 ton machines in this middle band: not the cheapest in China, but built to meet stricter market expectations.

5. What about engine and hydraulics – are parts available locally?

A 2 ton mini excavator is basically steel + engine + hydraulics + electronics.

Engine and hydraulics are the heart – and also the main after-sales cost.

Engine: what new importers normally worry about

- Will local workshops know this brand?

- Are filters, injectors, gaskets easy to buy locally?

- Does the engine meet local emission rules?

Common choices from serious Chinese factories:

- Kubota / Yanmar / Perkins engines for high-end markets

- Recognized Chinese brands for more price-sensitive markets

For Europe / North America:

- Many importers prefer globally known brands, so any local diesel shop can service the engine.

- Even when a Chinese engine is used, filters and basic parts are usually compatible with standard market parts.

Hydraulics: what matters most

Key components to ask about:

- Main pump brand and type

- Travel motor brand and type

- Swing motor brand

- Main control valve brand

Parts availability and repair options are much better when these components come from known global or strong domestic suppliers.

How to make engine & hydraulic choices as an importer

- For rebranding under a premium label in Europe / North America:

- Engine: choose a well-known international brand where possible

- Hydraulics: ask for recognized pump and motor brands

- This increases resale value and customer confidence

- For price-driven markets (some developing countries):

- High-quality Chinese engines and hydraulics can be acceptable

- Keep a small stock of critical spare parts in the local warehouse

Factories like Nicosail generally offer multiple configurations of engine and hydraulics for the same 2 ton model, so importers can pick the right balance between cost and brand recognition.

6. How to check quality before shipment as an overseas buyer?

This is a big pain point:

The machine is thousands of kilometers away. Once the container is closed, any problem becomes expensive.

Typical worries

- “What if the factory ships a different model?”

- “What if the paint and finish are much worse than in the photos?”

- “What if the performance is weak or the boom leaks?”

Practical ways to control quality from abroad

- Video inspection from the factory Ask the supplier to provide:

- A live video call or a detailed recorded video showing:

- VIN / serial number and nameplate

- Full 360° walk-around

- Close-ups of key welds, hoses, cylinders, engine bay

- Cold start of engine and at least 20–30 minutes of operation

- A live video call or a detailed recorded video showing:

- Factory test reports Serious factories have an EOL (end-of-line) test sheet listing:

- Pressure setting for hydraulic system

- Function test for each hydraulic movement

- Leakage check

- Noise and abnormal vibration check

- Third-party inspection For larger orders, many buyers use inspection companies to:

- Check machine quantity, model, and configuration

- Verify basic function

- Confirm correct color, logo and packaging

- Sample order before big volume A common strategy:

- First order: 1–2 units to test the supplier’s quality and communication

- Second order: full container after confirming machines perform well in the field

Factories like Nicosail are used to such step-by-step cooperation and typically support detailed photo/video reporting and sample orders before big commitments.

7. How do warranty, spare parts and technical support work?

Buying from China is not just a “one-time deal”.

If warranty and parts are not clear, profits disappear very fast.

Typical warranty terms for 2 ton China mini excavators

Most serious factories offer something like:

- 1 year or 1,000 hours for the whole machine (whichever comes first)

- Longer coverage for major structural parts (e.g., boom, arm, main frame) in some cases

Consumables are usually not covered:

- Filters, belts, seals, rubber tracks, bucket teeth, glass, etc.

Key points to clarify in the warranty

- What is the process if a failure happens?

- Photos + videos from end user

- Diagnosis together with the factory

- Parts shipped free if confirmed as quality issue within warranty

- Who pays freight for warranty parts?

- Often, factory covers the parts cost

- Freight cost can be negotiated – some factories cover small parcels

- Will the factory support remote diagnosis?

- Video calls with mechanics

- Wiring diagrams, hydraulic schematic

- Troubleshooting guides

Spare parts strategy for importers

Smart distributors treat spare parts as both:

- After-sales guarantee

- Profit center

Recommended approach:

- Order a starter parts kit with the first container:

- Filters, seals, pins & bushings, sensors, common hydraulic hoses

- One or two reserve cylinder kits, one extra main pump in high-volume markets

- Build a parts list from the factory with part numbers and photos

- Keep digital manuals and parts catalogs ready for end users and mechanics

Factories such as Nicosail usually provide:

- Exploded parts diagrams

- Part number lists

- Recommended spare parts package for each machine model

This makes it much easier for non-technical importers to build a basic parts business along with machine sales.

8. What is the real production and shipping lead time?

Many buyers have experienced this:

“Supplier said 15 days, then turned into 45 days. Peak season was missed.”

So, this is a very important question for new buyers of 2 ton mini excavators.

Factors affecting lead time

- Order quantity

- 1 unit vs a full container load

- Customization level

- Special color, logo, attachments, engine brand, cabin options

- Seasonality

- Before major holidays in China

- Global peak seasons for construction equipment

- Shipping space and schedules

- Vessel availability and port congestion

What is a reasonable expectation?

For a well-organized factory with multiple production lines (like Nicosail):

- Standard 2 ton mini excavator, common color, common engine:

- Production lead time often around 3–4 weeks, depending on season

- Heavy customization (special color, logo, cabin, unique attachments):

- Add another 1–2 weeks

Plus ocean shipping time, which depends on:

- Destination (Europe, North America, Australia, etc.)

- Port choice and shipping line

How importers can protect their schedule

- Ask for a detailed production plan per batch, not just a rough number of days

- Include delivery time clauses in proforma invoices or contracts

- Place orders early before local peak seasons (spring for construction, etc.)

- Stick to stable specs for main models, and avoid changing engine brands or colors last minute

Good factories usually send production and loading photos to keep buyers updated, so there are fewer surprises.

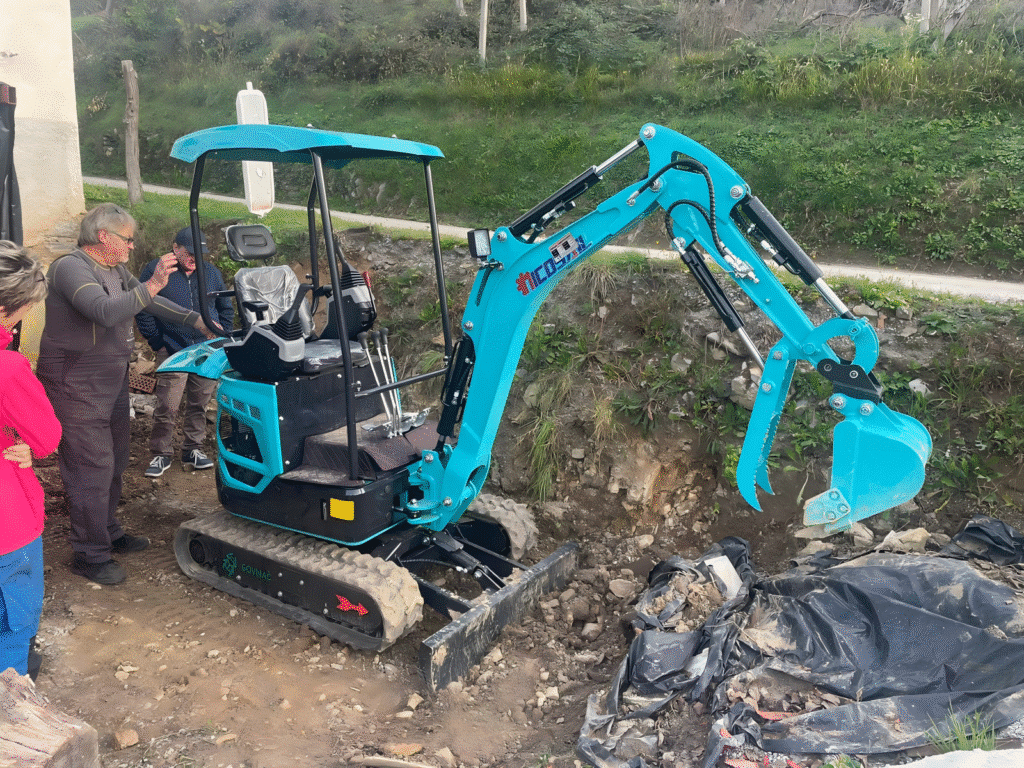

9. Can the 2 ton mini excavator be customized and rebranded?

For many distributors, branding is everything.

The machine must look like part of their own family, not just “another Chinese excavator”.

Common customization options

- Color and paint scheme

- Full body color change

- Two-tone scheme (upper structure one color, chassis another)

- Arm and boom in contrasting color

- Logo and decals

- Side logo decals

- Model number decals

- Warning labels in local language

- Control layout

- ISO / SAE control pattern

- Local language for decals and labels

- Attachments and packages

- Standard bucket sets

- Trenching bucket

- Hydraulic thumb, ripper, auger, quick coupler

- Customized attachment bundles for rental or farming packages

- Cabin / canopy options

- Open canopy

- Enclosed cabin

- With heater / fan / A/C (depending on model)

MOQ and extra cost

Most factories:

- Allow logo and color change from quite low quantities (sometimes even from 1–3 units for serious partners)

- For more complex changes (new metal covers, structural redesign), there may be:

- Engineering cost

- Higher MOQ

Nicosail, as a factory brand, commonly works with distributors who:

- Repaint or co-brand machines

- Use their own logo on the excavator and in marketing

- Keep the factory’s branding in some technical documents only

This kind of flexible branding allows importers to build their own brand value while still relying on a stable OEM factory behind the scenes.

10. What is the safest way to pay a new Chinese supplier?

Payment is always a sensitive topic, especially after stories about scams or bad experiences.

Common payment terms for new buyers

- 30% deposit, 70% balance before shipment (T/T)

- Letter of Credit (L/C) for larger and more formal orders

- Trade assurance / escrow-type services if available via certain platforms

How to reduce risk with a new supplier

- Start with a smaller test order

- 1–2 units or a partial container

- Use this to test quality, communication speed, and problem-handling attitude

- Verify the supplier’s identity

- Business license

- Factory photos and videos

- Factory address that can be found independently

- Align payment with inspection

- Deposit for production

- Final balance after inspection, before shipment

- For higher security, use third-party inspection before paying the balance

- Use clear written documents

- Proforma invoice with:

- Exact model and configuration

- Engine brand

- Attachments list

- Delivery terms (FOB, CIF, etc.)

- Lead time

- Purchase contract for larger volumes

- Proforma invoice with:

Factories like Nicosail are used to transparent cooperation with overseas buyers and usually accept inspection before final payment. This builds trust on both sides and reduces the risk of misunderstanding.

Quick Pre-Order Checklist

Before placing an order for a 2 ton mini excavator from China, a buyer can run through this quick checklist:

- Application fit

- Jobs suitable for a 2 ton machine are clearly understood

- No plan to use it like a 6 ton excavator

- Specifications confirmed

- Engine brand and emission level

- Hydraulic pump and motor brands

- Operating weight, bucket capacity, digging depth

- Certificates verified

- CE / EPA / other needed documents match the model and engine

- Samples of certificates checked carefully

- Price and inclusions clear

- Machine base price

- Attachment list

- Spare parts kit (if any)

- Shipping and insurance responsibility

- Quality control steps defined

- Video inspection / live call

- Third-party inspection if needed

- Factory test reports with serial numbers

- Warranty and parts policy written down

- Warranty period and coverage

- Process to claim warranty

- Initial spare parts package agreed

- Lead time and penalties clear

- Expected production and shipping time

- What happens if shipment is late

- Branding and customization confirmed

- Color, logo, decals, control pattern

- Any extra cost or lead time for customization

- Payment terms and risk control

- Deposit and balance schedule

- Inspection timing

- Security method for larger orders (L/C, etc.)

Choosing a mature factory such as Nicosail, which already exports 2 ton mini excavators to Europe, North America and Australia, usually makes it easier to tick all the boxes above with less back-and-forth.

Summary

New buyers of 2 ton China mini excavators usually share the same core concerns:

- Can this small Chinese excavator really do the jobs needed?

- Is the quality good enough, or will it damage my brand?

- Are the certificates real, and can the machine pass customs?

- Is the price reasonable for the chosen spec?

- Will the engine and hydraulic parts be serviceable locally?

- How can quality be controlled from another country?

- What about warranty, spare parts, and support after the sale?

- Will delivery be on time for the local selling season?

- Can it be rebranded and customized easily?

- Is there a safe way to pay a new supplier?

A well-chosen factory partner in China should be able to answer all 10 questions clearly, with:

- Transparent specifications

- Real certificates

- Solid end-of-line testing

- Clear warranty and parts policies

- Flexible branding and payment solutions

Brands like Nicosail, with multiple production lines and steady exports to strict markets, typically build their business by solving these exact concerns for international buyers.

With the right checks and communication, a 2 ton mini excavator from China can become a profitable and reliable product in any importer’s lineup, rather than a source of stress.

FAQ

Q1: Is a 2 ton China mini excavator suitable for rental fleets?

Yes, as long as the jobs match the machine size. For light construction, landscaping, farm work, and utility tasks, a 2 ton mini excavator from a serious factory can work very well in a rental fleet. Many rental businesses prefer sturdy, simple configurations with easy maintenance instead of high-end electronics.

Q2: How long can a 2 ton Chinese excavator last in normal use?

With proper maintenance and correct workload, many 2 ton machines from good factories can work reliably for several thousand hours. Lifetime depends strongly on how tenants use the machine, how often filters and oil are changed, and whether operators avoid severe overload and abuse.

Q3: Are rubber tracks from Chinese mini excavators reliable?

Rubber tracks are wear parts, no matter where they are produced. Quality depends on the track supplier. Good factories usually partner with stable track brands and can offer replacement tracks as spare parts. Importers often keep several sets in stock to avoid downtime.

Q4: Can a 2 ton mini excavator be transported easily?

Yes. One of the advantages of a 2 ton machine is easy transport. It can normally be moved on a small trailer behind a pickup or light truck (subject to local road regulations). This is very attractive for small contractors and farmers.

Q5: What information should be on the nameplate of a 2 ton mini excavator?

The nameplate should clearly show:

- Manufacturer name

- Model number

- Serial number

- Operating weight

- Engine power

- Year of manufacture

Certificates and customs inspectors often check that this information matches the documents, so correct plates are important.