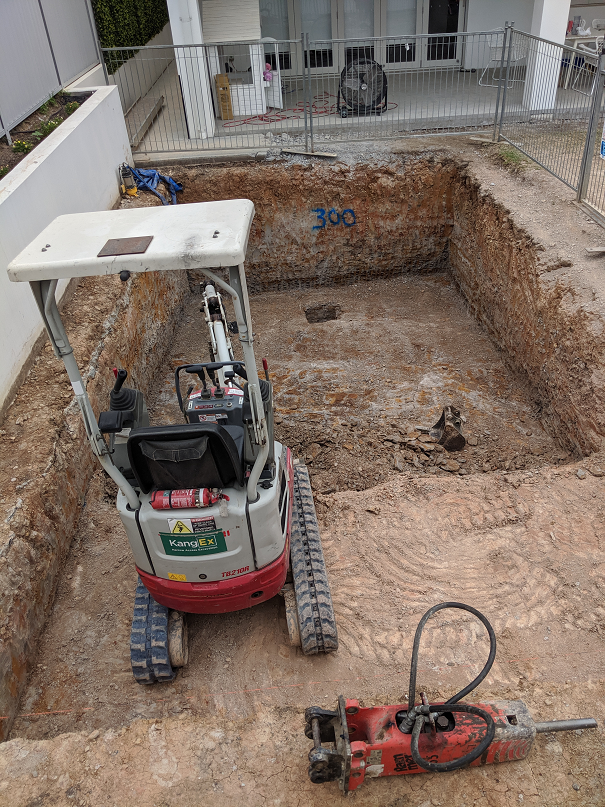

1. Why Mini Excavators Are Perfect for Pool Installation

Swimming pool installation is one of those jobs that looks simple on paper but gets tricky fast in real life. Tight backyards, narrow gates, existing landscaping, neighbors watching every move — all of that means big machines are often a problem, not a solution.

That’s why 1 ton and 2 ton mini excavators have become the go-to machines for residential and light commercial pool projects.

They are:

- Small enough to access backyards

- Strong enough to dig pool foundations

- Easy to transport on light trailers

- Cheap to run and maintain

For contractors, rental companies, and distributors, these machines hit a sweet spot: high demand, fast turnover, and broad use beyond pools.

2. Typical Pool Jobs and Real-World Challenges

Before choosing between a 1 ton or 2 ton mini excavator, it helps to look at what actually happens on a pool job.

Common situations include:

- Digging a 1.2–1.6 meter deep pool

- Working close to houses, fences, or garden walls

- Removing soil without damaging landscaping

- Leveling and trenching for pipes and drainage

- Backfilling after pool shell installation

The biggest challenges are:

- Limited space

- Soft or mixed soil

- Need for clean, precise digging

- Pressure to finish fast

This is where machine size makes a real difference.

3. 1 Ton Mini Excavator for Swimming Pool Installation

Where the 1 Ton Machine Shines

A 1 ton mini excavator is usually the smallest “real” excavator contractors consider. It’s often chosen for very tight residential jobs.

Typical advantages:

- Can pass through gates as narrow as 900 mm

- Extremely low ground pressure

- Easy to transport with small trucks or vans

- Simple operation, perfect for rental fleets

For small plunge pools, spa pools, or fiberglass pools, a 1 ton machine can absolutely do the job — especially in soft soil.

Realistic Limits of a 1 Ton Excavator

However, there are some things buyers need to understand clearly:

- Digging depth is limited

- Working speed is slower

- Bucket breakout force is modest

- Struggles in hard clay or rocky soil

In real projects, 1 ton machines often:

- Dig the initial shape

- Clean edges and corners

- Assist larger machines or manual work

They are precision tools, not power monsters.

4. 2 Ton Mini Excavator for Swimming Pool Installation

Why 2 Ton Is the Most Popular Choice

For most pool installers, 2 ton mini excavators are the best all-around solution.

They still fit residential spaces but offer:

- Deeper digging capacity

- Much stronger breakout force

- Faster cycle times

- Better stability on slopes

A 2 ton machine can usually:

- Dig full pool depth without repositioning too much

- Handle harder soil conditions

- Lift spoil more efficiently

- Work confidently with augers and breakers

The “One Machine Does It All” Advantage

Many contractors prefer 2 ton machines because they can:

- Dig the pool

- Trench for pipes

- Backfill and level

- Handle landscaping after installation

This versatility is why rental companies and distributors see higher ROI on 2 ton units.

5. 1 Ton vs 2 Ton: Which One Should You Choose?

Here’s a simple, practical comparison — no marketing talk.

| Factor | 1 Ton Mini Excavator | 2 Ton Mini Excavator |

|---|---|---|

| Access | Excellent | Very good |

| Digging Speed | Slow | Medium–Fast |

| Digging Depth | Limited | Suitable for most pools |

| Soil Adaptability | Soft soil only | Soft to medium-hard soil |

| Transport | Very easy | Easy |

| Rental Demand | Moderate | High |

| Overall Pool Work | Light-duty | Professional standard |

Simple rule:

- Choose 1 ton if access is extremely tight and pools are small

- Choose 2 ton if pool installation is a regular business

6. Key Specs That Actually Matter on Pool Jobs

Buyers often get distracted by engine brand names or paint color. For pool work, these specs matter more:

1. Digging Depth

Pools usually need 1.3–1.6 meters. A 2 ton machine reaches this comfortably.

2. Swing Stability

Good balance means cleaner walls and less rework.

3. Hydraulic Smoothness

Smooth hydraulics = neat pool shapes, especially near edges.

4. Cooling System

Pool digging often means continuous work in summer. Overheating kills productivity.

5. Track Width

Wider tracks reduce ground damage and improve safety near houses.

7. Attachments That Make Pool Work Easie

A mini excavator alone is good. With the right attachments, it becomes a pool installation system.

Common attachments include:

- Narrow buckets for pipe trenches

- Grading buckets for leveling

- Augers for drainage holes

- Hydraulic breakers for hard ground

Contractors using attachments often finish jobs 20–30% faster, based on factory feedback and customer reports.

8. Transportation, Access, and Backyard Reality

One overlooked advantage of 1–2 ton machines is logistics.

- Can be transported on light trailers

- No heavy truck license required in many regions

- Easy to maneuver without damaging lawns

For residential pool installers, this means:

- Lower transport cost

- Faster site setup

- Less risk of property damage claims

9. Reliability: What You Don’t See but Really Matters

This is where many buyers get burned.

Two machines may look identical in photos, but differences hide inside:

- Hydraulic hose quality

- Welding consistency

- Electrical layout

- Cooling system design

Factory-side data shows that most failures happen after 6–12 months, not during the first inspection.

Reliable machines are built with:

- Reinforced boom welding

- Clean hydraulic routing

- Tested pumps and valves

- Stable supplier chains

This “invisible reliability” is what separates tools from toys.

10. Why Many Buyers Source from China

China has become a major source for 1–2 ton mini excavators because:

- Complete supply chains

- Flexible customization

- Competitive pricing

- Fast production capacity

For distributors and rental companies, China sourcing allows:

- Private labeling

- Spec adjustments per market

- Better margin control

The key is choosing the right factory, not just the cheapest quote.

11. A Practical Look at the Nicosail Approach

Some factories focus only on low price. Others focus only on branding.

A balanced approach is what most professional buyers want.

Nicosail is often chosen by buyers who:

- Care about structural quality

- Want stable lead times

- Need export-ready machines for Europe, North America, and Australia

Rather than flashy features, the focus is on:

- Field-tested configurations

- Clear documentation

- Customization without chaos

This kind of approach fits pool installers who want machines that just work, season after season.

12. Common Buying Mistakes (and How to Avoid Them)

Mistake 1: Buying too small to save money

→ Ends up renting bigger machines later

Mistake 2: Ignoring hydraulic quality

→ Leads to jerky movements and poor finish

Mistake 3: No spare parts plan

→ Downtime kills peak pool season profits

Mistake 4: Believing only photos and videos

→ Always ask about internal components and testing

13. FAQ: Questions Pool Contractors Always Ask

Q1: Can a 1 ton mini excavator dig a full-size pool?

Yes, but slowly, and only in soft soil. Most professionals prefer 2 ton.

Q2: Is a 2 ton mini excavator too big for residential backyards?

Usually no. Most models fit through standard garden access.

Q3: Are Chinese mini excavators reliable enough?

Yes, if sourced from factories with stable production and export experience.

Q4: What’s the biggest advantage of 2 ton over 1 ton?

Speed, depth, and confidence in mixed soil conditions.

Q5: Can these machines be rented out after pool season?

Absolutely. Landscaping and utility work keep utilization high.

14. Final Summary

For swimming pool installation:

- 1 ton mini excavators are great for tight access and light-duty work

- 2 ton mini excavators are the professional standard for most pool projects

Choosing the right size saves:

- Time on site

- Labor cost

- Customer complaints

When sourced from the right Chinese factory and configured properly, these machines become reliable, profitable tools, not headaches.

That’s why experienced buyers look beyond price, focus on real-world performance, and increasingly choose balanced suppliers like Nicosail — not because of marketing, but because machines that work quietly in the background are what keep pool projects moving on schedule. 0