1. Why This Comparison Matters More Than Ever

Ten years ago, this question was simple.

Japanese mini excavators were considered “safe,” and Chinese ones were considered “cheap.”

Today, that old thinking no longer works.

Costs are rising everywhere. Labor is expensive. Shipping is unpredictable. Customers want machines that start every morning, don’t leak oil, and don’t destroy profit with downtime.

So the real question is no longer:

“Which country makes better machines?”

It is:

“Which machine fits your business model, budget, and risk tolerance?”

That’s what this guide breaks down — clearly, honestly, and without hype.

2. A Quick Background: How Chinese and Japanese Mini Excavators Evolved

Japanese Mini Excavators: Built on Consistency

Japan entered the compact excavator market early. Brands like Kubota, Komatsu, and Yanmar focused on:

- Precision manufacturing

- Long product cycles

- Conservative design changes

That’s why many 15-year-old Japanese machines are still working today.

Chinese Mini Excavators: Fast Learners, Fast Movers

China entered later — but learned fast.

Early machines had issues, no doubt. But over the last 8–10 years:

- CNC machining became standard

- Hydraulic suppliers upgraded

- Engines shifted to global brands

- Export certification became normal

Today, the gap is much smaller than most buyers expect.

3. Price: What You Really Pay vs What You Really Get

This is usually where buyers stop thinking — and where mistakes begin.

Typical Price Difference

- Japanese mini excavator: 30–60% higher

- Chinese mini excavator: Lower upfront cost

But price alone means nothing without context.

What Drives the Higher Japanese Price?

- Higher labor costs

- Strong brand premium

- Conservative production volume

- Dealer network costs baked into the price

Why Chinese Machines Cost Less

- Factory-direct sales

- Lower labor costs

- Flexible configurations

- Less brand markup

👉 Lower price does NOT automatically mean lower quality — but it does require smarter supplier selection.

4. Quality & Reliability: The Truth Behind the Reputation

This is the most emotional topic — and the most misunderstood.

Japanese Strengths

- Very stable hydraulic tuning

- Excellent long-term consistency

- Tight quality control across batches

Chinese Reality Today

Quality now depends on which factory, not which country.

A good Chinese factory:

- Uses robotic welding

- Pressure-tests hydraulics

- Tracks serial numbers

- Runs load testing before shipment

A bad one:

- Mixes suppliers every month

- Skips inspection

- Chases the lowest price

That’s why buyers saying “Chinese machines are unreliable” often bought from the wrong supplier, not from the wrong country.

5. Components That Matter: Engine, Hydraulics, Steel, and Wiring

Let’s break this down simply.

Engine

- Japanese brands: In-house engines or long-term partners

- Chinese brands: Often Kubota, Yanmar, Perkins, or EPA-compliant Chinese engines

👉 Engine quality is no longer a deciding factor if correctly specified.

Hydraulics

This is where machines feel “smooth” or “cheap.”

Good Chinese factories now use:

- Imported valves

- Better hose crimping

- Stable pump suppliers

Cheap factories don’t — and buyers feel it immediately.

Steel & Structure

Modern Chinese factories use:

- Q355 structural steel

- Laser cutting

- Robotic welding

The days of thin steel and cracked booms are mostly gone — if the factory exports seriously.

6. Certification & Compliance: CE, EPA, and the Risks Buyers Miss

This is a big pain point for importers.

Japanese Brands

- Certifications are stable and genuine

- Documents match serial numbers

Chinese Brands

Two realities exist:

- Professional exporters → real CE, real EPA, verifiable

- Trading companies → copied documents, risky shortcuts

👉 This is not a “China problem.”

It’s a supplier credibility problem.

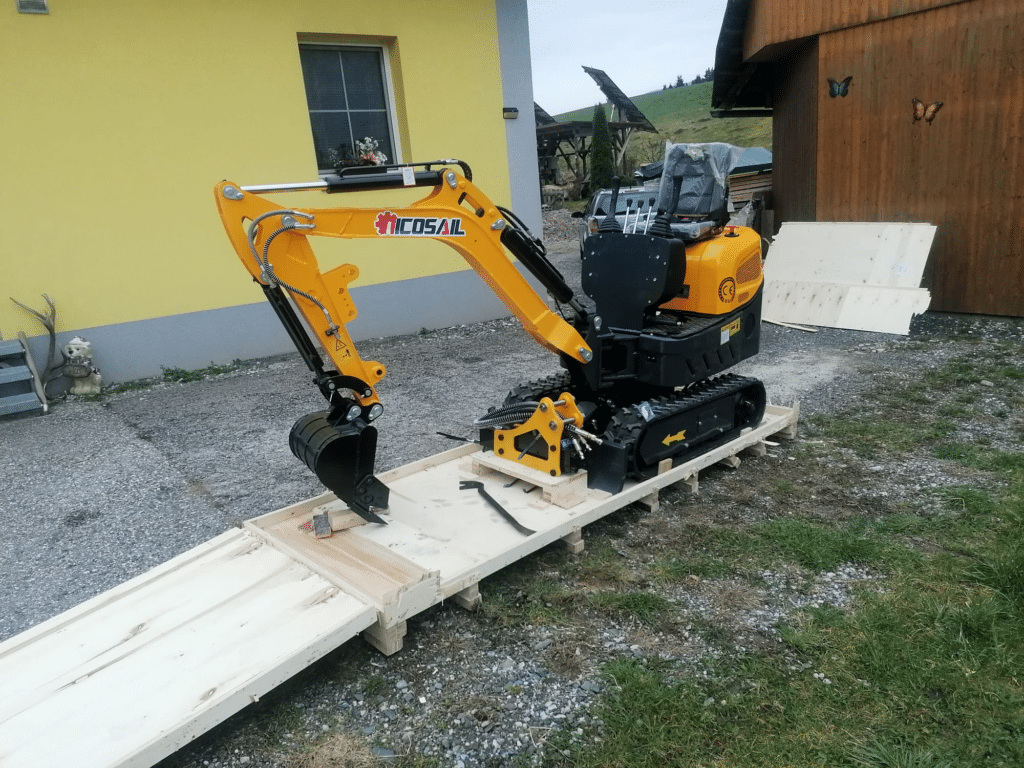

A factory like Nicosail, which exports long-term to Europe and North America, treats certification as part of production — not paperwork at the end.

7. Customization & Branding: Where Chinese Factories Have an Edge

This is where Japanese brands rarely compete.

Chinese factories can offer:

- Custom colors

- OEM branding

- Cab layout adjustments

- Hydraulic options for attachments

For distributors and rental companies, this matters.

Japanese brands sell their product.

Chinese factories help sell your brand.

8. Delivery Time, Logistics, and Supply Chain Reality

Japanese Brands

- Stable production

- Longer lead times

- Fixed configurations

Chinese Factories

- Faster production

- Container-based shipping

- Flexible batch sizes

During peak seasons, this flexibility can decide whether a distributor wins or loses a year.

9. After-Sales Support & Spare Parts Availability

This is where many buyers hesitate — understandably.

Japanese Brands

- Global dealer networks

- Easy parts ordering

- Higher part prices

Chinese Brands (Good Factories)

- Common hydraulic parts

- Engine parts available locally

- Direct factory support

The key question is not:

“Do parts exist?”

It is:

“Will the factory respond after payment?”

That’s where experienced exporters stand out.

10. Resale Value: Short-Term Cost vs Long-Term Return

Japanese machines still win here — no argument.

But resale value only matters if:

- You sell used equipment regularly

- Your market values brand over condition

In many regions, buyers care more about:

- Hours

- Condition

- Price

Chinese machines with proper maintenance hold value far better than people expect.

11. Which One Is Better for Different Buyers?

Choose Japanese Mini Excavators If:

- Brand image is critical

- Budget is flexible

- Long-term ownership is the priority

- Dealer support is required

Choose Chinese Mini Excavators If:

- ROI matters

- You are a distributor or importer

- Custom branding is important

- You want factory-direct pricing

12. A Practical Buying Checklist (Avoid Costly Mistakes)

Before choosing any machine, ask:

- Who makes the hydraulics?

- Can serial numbers be traced?

- Are certifications verifiable?

- What happens if a hose fails?

- Can spare parts be shipped in 48 hours?

If a supplier hesitates — walk away.

13. Where Brands Like Nicosail Fit in This Comparison

Some Chinese brands are positioned between cheap and premium.

Nicosail focuses on:

- Stable export configurations

- Consistent suppliers

- Certification-ready production

- Factory accountability

That’s why many buyers who once used Japanese machines now use Chinese ones without sacrificing reliability — while improving margins.

14. FAQs Buyers Always Ask

Q1: Are Chinese mini excavators reliable long-term?

Yes — if sourced from an export-focused factory with stable components.

Q2: Why are prices so different between suppliers?

Different hydraulics, steel thickness, inspection standards, and engines.

Q3: Can Chinese machines meet EU and North American standards?

Yes. Many already do — when built for those markets.

Q4: Is Japanese quality still better?

In consistency, yes. In value-for-money, not always.

15. Final Summary: Make the Choice That Fits Your Business

This is no longer a battle between countries.

It is a decision between:

- Brand premium vs cost efficiency

- Dealer comfort vs factory flexibility

- Old assumptions vs new reality

Japanese mini excavators remain excellent machines.

Chinese mini excavators have grown into serious, professional equipment.

The best choice is the one that:

- Fits your market

- Protects your cash flow

- Keeps machines working instead of waiting for parts

Choose wisely — and you won’t regret either path.