A small excavator business (rental, contracting, resale, or farm work) lives and dies by uptime. A machine can be strong, paint can look great, and price can be attractive—but if a $12 seal or a $25 sensor stops the excavator for 10 days, profit disappears fast.

When buying from a China supplier, spare parts access is not “after-sales service.” It is part of the purchase decision, just like engine choice, hydraulics, and certification. The goal is simple: make sure parts are available, identifiable, and shippable—before the first machine arrives.

This guide shows a practical system to secure spare parts with a China supplier, step by step, in plain language.

1. Why spare parts access decides profit (more than machine price)

Small excavator owners usually worry about:

- Will the machine be reliable?

- Will the supplier ship on time?

- Will certificates be real?

- Can parts be found locally?

Here’s the uncomfortable truth: even reliable machines need parts, because wear items are designed to wear out. Bushings, filters, seals, rubber tracks, sprockets, hydraulic hoses—these are normal consumables. If parts are slow or confusing to order, downtime becomes the hidden cost that eats margins.

A simple way to see it:

- A mini excavator earning $180/day in rental or contract work loses $1,800 in 10 days downtime.

- That can wipe out the “saved money” from a lower purchase price immediately.

So the smart question is not “Are parts cheap?”

It’s “Can the right parts arrive fast, every time, without mistakes?”

2. Know the parts: fast-wear vs. slow-wear vs. “rare but deadly”

To ensure easy access, parts should be grouped. This avoids stocking everything (too expensive) or stocking nothing (too risky).

H3: Fast-wear parts (high frequency)

These should be easy to order and often kept in local stock:

- Filters (engine oil, fuel, air, hydraulic return)

- Seals and O-rings (hydraulic cylinders, pumps, valves)

- Pins and bushings (bucket linkage)

- Rubber tracks, track rollers, idlers, sprockets

- Teeth, side cutters, bucket pins

- Belts, hoses, clamps

- Electrical small parts (switches, relays, fuses)

H3: Slow-wear parts (medium frequency)

Often ordered quarterly or based on usage:

- Alternator, starter motor

- Radiator, water pump

- Travel motor seal kits

- Joystick assemblies

- Swing bearing grease seals

- Hydraulic pump couplers

H3: Rare but deadly parts (low frequency, high downtime)

These are not needed often, but when they fail, the machine may be fully down:

- Main hydraulic pump

- Travel motor assembly

- Swing motor assembly

- Control valve

- ECU / main controller (for models with electronics)

- Wiring harness

The strategy: stock fast-wear locally, have a rapid route for rare-but-deadly.

3. Build a “Parts Promise” before paying the deposit

Before a deposit is sent, the supplier should confirm in writing:

- Parts availability period (example: 5–10 years)

- Standard lead time for common items (example: 3–7 days to dispatch)

- Express shipping options and who pays

- How parts are identified (part numbers + diagrams)

- How warranty parts are handled

- Whether the supplier keeps inventory or buys after the order

A supplier that avoids these topics early often becomes “slow and vague” after shipment.

A practical way to phrase it:

- “Parts support is part of the purchase. A clear spare parts system is required before mass order.”

4. The golden rule: one accurate parts list beats ten promises

The number one reason buyers struggle with China spare parts is not price. It’s wrong parts ordered because identification is weak.

So the most valuable document is:

- Exploded-view parts catalog

- BOM (bill of materials)

- Part numbers + photos

- Machine serial number rules

- Supplier contact and response time

If a supplier cannot provide a clean parts book, expect delays, back-and-forth messages, and mistakes.

What “good” looks like:

- Each machine has a model code and serial range

- Each assembly has a clear diagram

- Each part has a unique part number

- Wear parts have clear size specs (length, diameter, teeth pitch, etc.)

- Filter references are listed (or cross-referenced)

This is how parts become “easy,” even across borders.

5. How to check if the supplier is truly parts-ready (factory reality checks)

Some suppliers “say yes” to parts support but do not run a parts system.

Here are practical checks that work even on video calls:

H3: Ask to see the spare parts warehouse (live video)

A real parts-ready factory can show:

- Shelves with labeled bins

- Common items stocked in quantity

- Packing station for small parcels

- Barcode/QR labels or at least consistent labeling

A factory with no parts shelves usually means:

- Parts are purchased only after you order

- Lead times become unpredictable

H3: Ask for 20 common wear parts prices within 24 hours

If the supplier can quote quickly and consistently, the internal system exists.

If the supplier replies slowly, with missing info, or changes part names each time, parts ordering will be painful later.

H3: Ask a “trick” question: “What’s the filter part number for this model?”

A prepared supplier answers with:

- Part number + photo + dimensions (or cross reference)

An unprepared supplier answers with:

- “It’s standard filter, don’t worry.”

“Don’t worry” is not a part number.

6. Minimum spare parts package: what to ask for (by tonnage)

A smart supplier should offer a recommended spare parts kit with the machine order. If not, request one.

Below is a practical baseline (adjust by working intensity).

H3: For 1–2 ton mini excavators

- Full filter set × 3

- Hydraulic cylinder seal kits (boom/arm/bucket) × 1 each

- Assorted O-ring box (hydraulic standard) × 1

- Bucket teeth set × 2

- 2–4 hydraulic hoses (most exposed lines) × 1 each

- Track roller × 1

- Idler seal kit × 1

- Electrical fuses/relays set × 1

- Fan belt × 1

H3: For 2.5–3.5 ton mini excavators

Add:

- Track roller × 2

- Sprocket × 1

- Return roller × 1

- Joystick boot and common switches × 1

- Travel motor seal kit × 1

H3: For dealers / rentals buying multiple units

Request a “fleet kit” that serves 5–10 machines:

- Filters × 20–30 sets

- Seal kits × 5–10 sets

- Rubber track × 1–2 pairs (depending on model)

- One “rare but deadly” item strategy (see Section 13)

The idea is not to overbuy. It’s to cover the parts that stop work most often.

7. How many parts to stock: simple math for dealers and fleet owners

A clean stocking method:

H3: Step 1 — estimate running hours

Example:

- Rental unit: 70–120 hours/month

- Contractor unit: 40–90 hours/month

- Farm/landscaping: 20–60 hours/month

H3: Step 2 — match service intervals

Typical service patterns:

- Engine oil/filter: every 100–250 hours (depends on engine and conditions)

- Hydraulic return filter: around 500 hours

- Grease and inspection: daily/weekly

H3: Step 3 — keep “two cycles” of consumables locally

If engine filter is every 250 hours and a machine runs 100 hours/month, that’s about 2.5 months per service.

Two cycles means keeping enough for 5 months.

This avoids emergency shipping for normal maintenance.

H3: Step 4 — use the “80/20” rule for parts

In most small excavator fleets:

- 80% of part orders come from 20% of parts (filters, seals, hoses, undercarriage wear items)

So local stock should focus on that 20%.

8. Lead time, shipping, and customs: making parts arrive before the machine breaks

Even if the supplier has parts, shipping choices decide whether parts feel “easy” or “impossible.”

H3: Use two shipping lanes

- Express lane (3–10 days): for downtime emergencies

- Consolidated lane (20–45 days): for routine replenishment

Parts should be shipped separately from machines when needed. Waiting for the next container is how small problems become big losses.

H3: Standardize packaging and labels

Request:

- Part number label outside the bag

- Photo label for confusing items (left/right parts)

- QR code linking to the diagram (if supplier supports it)

H3: Avoid the “customs surprise”

Spare parts sometimes face different HS codes than whole machines. Ask the supplier to:

- Provide a consistent packing list

- Provide correct part descriptions (not “metal parts”)

- Provide weights and quantities clearly

This reduces customs delays and avoids incorrect declarations.

9. Part numbers, manuals, and QR codes: stopping wrong parts orders

Wrong parts are the #1 hidden cost in spare parts management.

A simple system fixes it:

H3: Require the “3-key rule” for every parts order

Every parts order should include:

- Machine model

- Machine serial number (or production batch)

- Part number from the catalog

Photos help, but photos alone are risky because many parts look similar.

H3: Build a shared parts folder

Dealers and fleet owners should store:

- Parts catalog PDF

- Service manual PDF

- Filter list

- Under carriage specs

- Electrical diagram (if available)

- Warranty terms

This becomes the internal “parts brain,” so staff can order without guesswork.

10. Interchangeable parts: smart standardization without quality risk

Many mini excavators use common market parts (filters, seals, bearings). That can be a big advantage—if done correctly.

H3: What can be safely standardized?

Often safe:

- Filters (with correct size/spec)

- Common seal sizes

- Bearings with standard codes

- Hoses (if pressure rating and fittings match)

H3: What should NOT be “generic” without testing?

Be careful with:

- Hydraulic pumps and control valves

- Travel motors and swing motors

- Electrical controllers/ECUs

- Injectors and engine sensors

Generic versions may fit but can cause performance issues or early failure.

Best practice:

- Keep genuine or factory-approved for core hydraulic and electrical parts

- Standardize consumables and simple hardware where safe

11. Quality control for spare parts: avoiding cheap surprises

Cheap spare parts are expensive when they fail twice.

A practical quality check approach:

- Ask the supplier to provide material or brand info for key wear items

- Example: track rubber compound grade, roller hardness spec, seal material type

- Request incoming inspection photos for the first batch of spare parts

- For critical items, ask for one sample shipped first (especially seal kits and hoses)

Also, check consistency:

- Same part number should come in the same packaging and same finish every time

- If packaging and look changes every order, supply chain is unstable

12. Contract terms that protect spare parts supply (SLA + penalties)

A good spare parts agreement is simple and measurable.

H3: Add a Spare Parts SLA (Service Level Agreement)

Include items like:

- Quote response time: within 24 hours on working days

- Dispatch time for stocked items: 3–7 working days

- Emergency dispatch option: within 48 hours (paid express)

- Warranty claim response time: within 48 hours

H3: Add real consequences (soft penalties)

Examples:

- Late dispatch credit (small % discount on that parts order)

- Free express upgrade if delay is supplier fault (for warranty parts)

This is not about fighting. It’s about building a system the supplier respects internally.

13. Building a long-term spare parts pipeline (local warehouse, consignment, VMI)

For dealers, importers, and rental companies, the best solution is a two-level inventory:

H3: Level 1 — local fast-wear stock (your side)

- Filters, seals, teeth, hoses, undercarriage basics

This covers most daily needs.

H3: Level 2 — supplier emergency stock (factory side)

- Rare but deadly items kept ready

This protects against the “one failure stops everything” scenario.

If volume grows, consider:

- Consignment stock: supplier places parts in your warehouse, pay when used

- VMI (Vendor Managed Inventory): supplier monitors stock and replenishes automatically

- Regional partner warehouse: supplier cooperates with a local service company

These systems are common in mature brands, but they can also be built with China suppliers if the relationship is stable and volume is real.

14. A practical example: setting up a parts system with a China supplier

Here is what a clean setup looks like for a small excavator dealer importing 10–20 units per quarter:

- Before first order: request parts catalog + filter list + recommended spare kit

- With machine shipment: include spare kit for each machine + one fleet kit for 5 units

- Create internal stock list: top 50 fast-moving part numbers

- Monthly: order replenishment by consolidated shipping lane

- Emergency plan: agree on express lane procedure (who pays, how fast, what documents)

- After 3 months: review which parts actually moved, adjust stocking

- After 6–12 months: consider consignment for slow movers but high downtime risk

This system keeps parts “boring”—and boring is good. It means downtime is controlled.

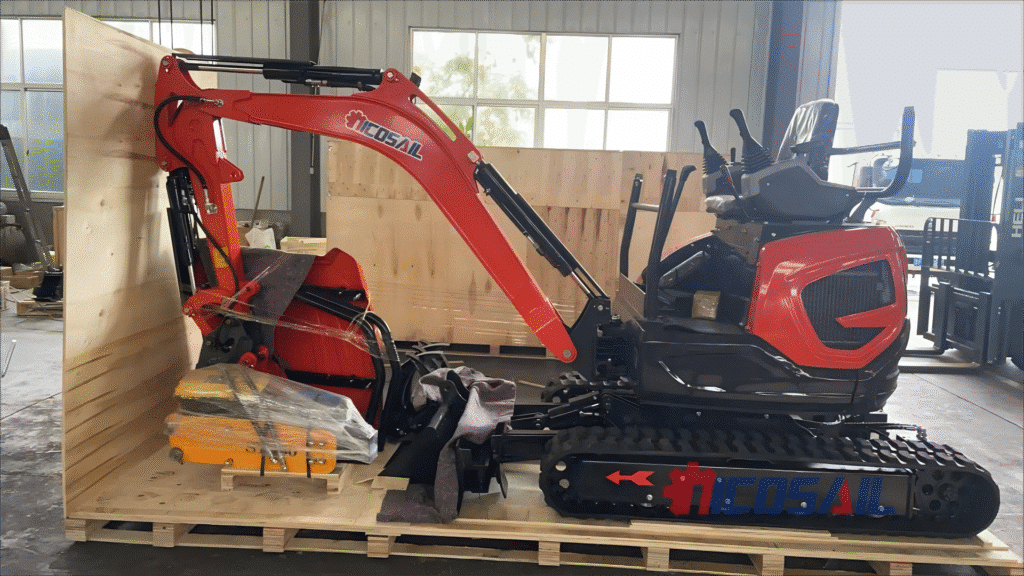

15. Why brands like Nicosail can make parts easier

Not every factory runs the same way. Some factories focus only on shipping machines. Others treat spare parts as a separate product line with its own warehouse, labeling, and after-sales process.

When choosing a supplier like Nicosail, buyers should look for practical signs:

- Clear parts catalog and stable part numbers

- Standard spare parts kits available for each model

- Fast quoting and consistent packing

- Ability to support both bulk replenishment and urgent express orders

- Willingness to define parts support terms before bulk purchase

That’s the kind of supplier behavior that turns “China sourcing risk” into a manageable system—especially for importers and rental fleets that cannot afford long downtime.

FAQ

1) What is the biggest mistake when buying a mini excavator from China regarding spare parts?

Relying on verbal promises instead of getting a parts catalog, part numbers, and dispatch rules in writing. Without part numbers, wrong parts and delays become common.

2) Should spare parts be purchased together with the first machine order?

Yes. At least a basic spare kit should arrive with the first shipment, so the machine can be maintained and small failures don’t become downtime disasters.

3) How many filters should be stocked per machine?

A practical baseline is two service cycles worth locally (based on hours/month). For many users, that means 2–3 full filter sets per machine to start.

4) Is it safe to buy “generic” spare parts locally?

For many consumables (filters, seals, bearings, hoses), it can be safe if specs match. For core hydraulic and electrical parts, it’s safer to use factory-approved parts unless a proven equivalent exists.

5) How can wrong parts orders be reduced?

Use the “3-key rule”: machine model + serial number + part number from the catalog. Photos help, but part numbers are the real solution.

6) What lead time is reasonable for spare parts from China?

For stocked items, many suppliers can dispatch within about a week. Shipping time depends on method: express is faster but costs more; consolidated shipping is slower but economical.

7) What if the supplier changes parts designs during production?

That risk is controlled by serial-number-based parts catalogs and clear revision tracking. Buyers should require the supplier to confirm part changes and keep compatibility notes.

8) Do dealers really need a local parts warehouse?

If selling or renting multiple units, yes. Even a small shelf of the top fast-wear parts dramatically improves customer satisfaction and repeat sales.

Final Recap

Easy spare parts access is not luck—it’s a system. The system starts before the deposit and includes: a real parts catalog, stable part numbers, a starter spare kit, a simple stocking plan, two shipping lanes, and clear SLA terms. With those basics in place, buying small excavators from a China supplier can be profitable and predictable instead of stressful.

If the supplier can show a real parts warehouse, quote quickly, label parts consistently, and support both routine replenishment and urgent dispatch, spare parts stop being a fear—and become a competitive advantage. Brands that operate with that mindset (including suppliers like Nicosail) typically make life much easier for importers, rental fleets, and contractors who care about uptime more than anything else.