1) Why “Good Communication” Is the Real Quality Control

When importing small excavators from China, most problems don’t start on the factory floor. They start in the chat.

- A buyer says “EPA engine” but doesn’t specify the exact engine model or certificate format needed.

- A buyer says “quick hitch” but doesn’t define pin size, center distance, or coupler standard.

- A buyer says “deliver in 30 days” without defining from which date the countdown starts.

Then the machine arrives, and it’s not “wrong,” but it’s not what was expected. That’s the worst kind of conflict—because both sides feel they’re right.

Effective communication does two things:

- Turns “expectations” into written, measurable specs

- Creates checkpoints so issues are caught early, when they’re cheap to fix

If communication is tight, quality gets easier. If communication is loose, even a good factory can deliver a disappointing result.

2) Pick the Right Channel: Email vs WeChat/WhatsApp vs Video Calls

Chinese suppliers often live on WeChat. Overseas buyers often live on email. The best approach uses both—each has a job.

Use email for “things that can become evidence”

Email is best for:

- final specifications and drawings

- contract terms, payment terms, delivery terms

- confirmed lead time

- packing list requirements

- certificate requirements

- change orders (any changes after confirmation)

Rule: if it affects money, time, legality, or performance, put it in email.

Use WeChat/WhatsApp for speed and daily coordination

Chat apps are great for:

- quick clarifications

- photo/video updates

- factory progress snapshots

- shipping booking updates

- small technical confirmations (“Is the boom hose sleeve added?”)

Rule: chat is for momentum, email is for confirmation.

Use video calls to eliminate “lost in translation”

A 15-minute video call can replace 50 messages when discussing:

- custom decals + paint color

- attachments and couplers

- cab/canopy layout

- control pattern and joysticks

- packaging and container loading plan

Pro tip: record the call (with permission) and summarize decisions by email right after.

3) The #1 Rule: Write Specs Like an Engineer, Not Like a Shopper

Suppliers can’t build “high quality.” They can only build defined parts, defined processes, defined tests.

Replace vague words with measurable ones:

- “Strong boom” → “boom plate thickness, reinforcement design, weld standard, fatigue focus areas”

- “Good hydraulics” → “pump type, rated flow, main valve brand/model, relief pressure targets, travel motor type”

- “Fast delivery” → “production days + packing days + port days, based on confirmed deposit date”

If the supplier is professional, they’ll appreciate the clarity. If they resist clarity, that’s a signal too.

4) The “3-Layer Spec Sheet” That Prevents 80% of Disputes

A simple structure works extremely well for mini excavators:

Layer 1: Non-negotiables (must match)

These are deal-breakers:

- model / operating weight class (1t / 1.8t / 2.5t / 3.5t / 5t, etc.)

- engine brand/model and emission requirement (if any)

- hydraulic pump type (gear vs piston) and target flow

- swing motor type, travel motor type

- track width, shoe type, undercarriage options

- canopy or cab, AC/heater requirements

- attachments list (bucket size, auger, breaker piping, quick coupler)

- voltage standard and lighting

- paint and corrosion expectations (especially for coastal markets)

Layer 2: Options (choose from a menu)

This avoids endless custom confusion:

- auxiliary hydraulic lines (single/double acting)

- thumb clamp type

- quick coupler style (pin grabber, wedge lock, etc.)

- joystick pattern (ISO/SAE, if applicable)

- seat type, armrest, safety bar, travel alarm

- rubber vs steel tracks

- extra counterweight

Layer 3: Acceptance standards (how “OK” is judged)

This is where many buyers forget to communicate:

- what tests are required before shipment (cold start video, travel test, swing test)

- what documents must be in the file (inspection report, serial numbers, photos)

- packaging standard (wood thickness, fumigation stamp, rust prevention)

If the supplier can sign off on these three layers, the order becomes controllable.

5) Photos, Videos, and Serial Numbers: What to Ask For (and When)

Instead of asking “Send some photos,” ask for specific proof at specific times.

Before production (day 1–3)

Ask for:

- confirmed configuration sheet with signatures/stamps

- decal design proof (PDF)

- paint color code confirmation

- engine nameplate photo (if engine is stocked already)

During production (mid-point)

Ask for:

- undercarriage assembly photos (rollers/idler/track tension)

- hydraulic hose routing photos (especially around boom and swing area)

- welding area photos (boom, arm, dozer blade bracket if applicable)

After assembly (before packing)

Ask for:

- full walk-around video with machine running

- serial number plate photo

- engine nameplate photo

- hour meter photo (should be minimal)

- function test clips: travel forward/backward, swing left/right, boom/arm/bucket smoothness

- auxiliary line pressure/flow check (if attachments rely on it)

Small detail that saves big trouble: request photos that include a piece of paper showing the date and PO number. It reduces the risk of recycled media from old orders.

6) Managing Time Zones, Holidays, and Response Speed Without Stress

A lot of buyers get frustrated because they expect replies in their own daytime. China is often 8–16 hours ahead.

Simple working rhythm that works

- One “daily bundle” message: send a single message with all questions, numbered

- Ask the supplier to reply by referencing the numbers

- Keep a shared document (Google Doc/Sheet) for open points

Watch out for China’s big shutdown weeks

- Chinese New Year (often a long stop, with workers traveling)

- National Day / Golden Week (early October)

The exact dates change each year, but the impact is consistent: production slows, shipping gets crowded, response time can lag.

Best practice: during those periods, focus communication on planning, not rushing. Lock the schedule before the holiday rush.

7) Cultural Gaps That Cause Expensive Mistakes (and How to Avoid Them)

This part matters more than most people want to admit.

“Yes” can mean “I understand,” not “I guarantee”

A salesperson may say “Yes, no problem” to keep the conversation smooth. It might mean:

- “Understood, checking now”

- “Should be OK, but not verified”

- “Technically possible, but needs extra cost/time”

Fix: ask the supplier to respond in a confirming format:

- “Confirmed / Not confirmed / Need extra cost / Need extra days”

This forces clarity.

Avoid making someone “lose face”

If a mistake happens, attacking the person often slows everything down. The goal is to fix the order, not win an argument.

Better language:

- “Looks like there’s a mismatch with the spec sheet. Let’s align and correct it.”

- “To avoid a repeat, let’s add this checkpoint next time.”

That tone keeps cooperation strong while still being firm.

Decision-making can be hierarchical

Sometimes the salesperson can’t approve changes. Engineers or the boss must confirm.

Fix: ask early:

- “Who signs off on engineering changes and lead time changes?”

Then include that person in key discussions when needed.

8) Price Talk: How to Negotiate Without Breaking Cooperation

Low price is good. But “pressure until angry” is not a strategy.

What works better than pushing the unit price down

Ask for value improvements that reduce long-term risk:

- upgrade hose protection sleeves in high-wear zones

- better cylinder seals (if offered)

- stronger packing and rust prevention

- add EOL (end-of-line) test report

- add spare parts kit with the shipment

These are usually easier for a factory to agree to than a deep price cut, and they reduce warranty pain later.

Use “target + reason,” not just “lower”

Example:

- “Target price is X because the market retail is Y and margin must cover warranty and local support. What configuration or packaging adjustments can help meet X without risk?”

That keeps the conversation professional.

9) Lead Time Truth: How to Lock a Realistic Schedule

Many buyers hear “25–30 days” and assume it’s guaranteed. Often it isn’t.

Define the start date clearly

Lead time should be counted from:

- deposit received date and

- final configuration confirmed date and

- decal/paint proof approved date (if custom branding exists)

If any of those are missing, “lead time” becomes fantasy.

Break lead time into phases

Ask for:

- components preparation time (engine, pump, valves)

- welding/assembly time

- testing time

- packing and warehouse time

- booking vessel time (this is often the hidden delay)

A good supplier can provide a simple timeline. If the supplier can’t explain their timeline, it’s risky.

10) Quality Control Communication: The Exact Checkpoints That Work

Quality control isn’t just hiring a third-party inspector. It’s communicating what to inspect and when.

Three checkpoints that work well for mini excavators

- Pre-production confirmation

- signed spec sheet

- decals and paint confirmed

- In-process check (50–70%)

- hose routing, weld zones, undercarriage assembly

- Pre-shipment inspection (PSI)

- function test

- leak check

- noise/abnormal vibration check

- appearance and paint check

- packing check

What to tell the inspector (or supplier) to focus on

Mini excavators often fail buyers on “small but painful” issues:

- hydraulic oil leaks at fittings after transport vibration

- hoses rubbing on sharp edges

- loose electrical connectors

- paint thin at corners/edges

- bucket pin clearance too tight/too loose

- track tension not set correctly

If the supplier can provide an EOL test routine and a PSI checklist, that’s a big green flag.

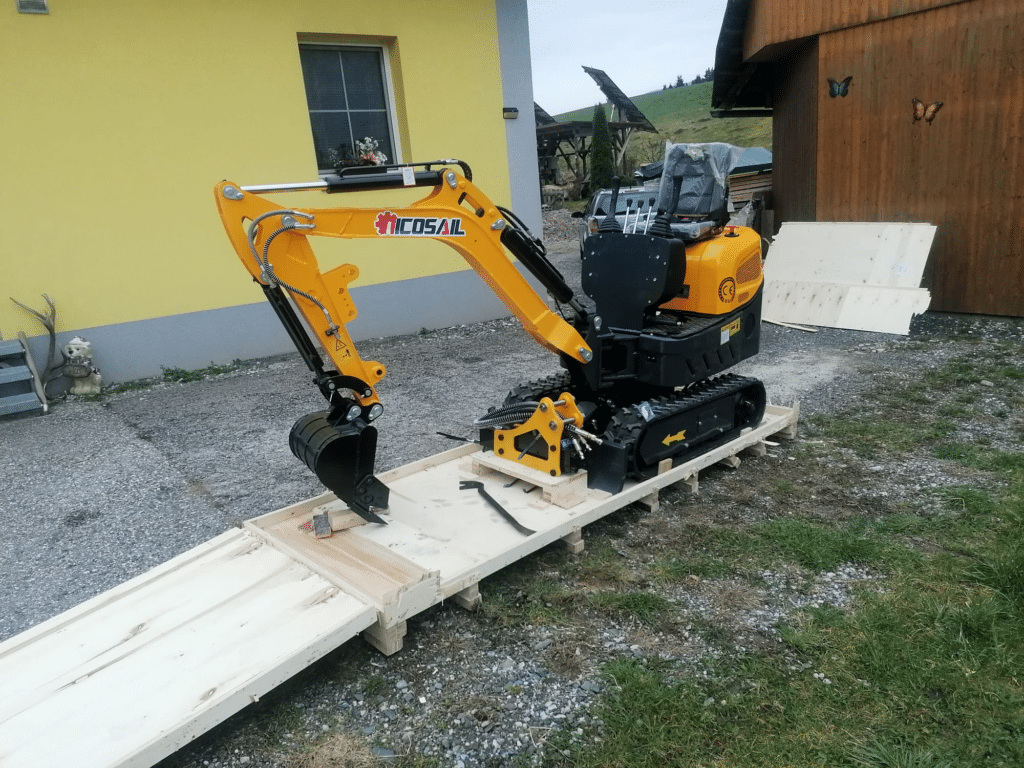

Example of a supplier that tends to communicate well on QC: brands like Nicosail often support orders with clear checklists, serial number tracking, and photo/video documentation at key stages—without making the whole process feel heavy or slow. The point isn’t the logo; it’s the system.

11) Certifications & Compliance: How to Reduce Fraud Risk

Some buyers get burned by fake or mismatched certificates. This happens most often when:

- the certificate doesn’t match the exact model

- the certificate belongs to another company

- the certificate is real but not applicable to the shipped configuration

Safer communication steps

- Request certificate number + issuing body name early

- Request high-resolution scan and compare company details

- Request nameplate photo (serial/model) and ensure it matches paperwork

- Put certificate requirements in the contract and final spec sheet

If a supplier becomes defensive about providing verification details, treat that as risk—not “normal supplier attitude.”

12) Logistics Language: Incoterms, Packing, and What “Ready” Really Means

A lot of confusion comes from logistics words that mean different things to different people.

Common Incoterms realities

- EXW: buyer handles pickup; high control, higher coordination effort

- FOB: supplier delivers to port and clears export; common and practical

- CIF: supplier arranges freight to destination port; easier but less transparent

- DDP: supplier delivers to door with duties (varies by country feasibility)

The key is this: “ready” should mean packed, labeled, documented, and available for pickup, not “almost done.”

Packing details worth communicating

- machine fixation points inside container

- anti-rust protection method (especially if sea transit is long)

- spare parts packing list and labels

- whether battery is installed or shipped separately

- whether fuel/oil is drained (some shipping rules require it)

Ask for packing photos before container door seals.

13) Payment Terms: How to Protect Cash Flow Without Insulting the Supplier

Payment is a trust topic. The best approach is firm but respectful.

Common structures

- deposit + balance before shipment

- deposit + balance after inspection

- LC for larger orders (if the supplier supports it)

If asking for better terms, tie it to risk control:

- “Balance after third-party PSI and photo/video confirmation of packing.”

That sounds reasonable and professional.

Also helpful: agree on what happens if inspection fails (rework timeline, reinspection, cost responsibility). Put it in writing.

14) Handling Changes: The Right Way to Do Change Orders

Changes are normal. The problem is untracked changes.

Simple change order rule

Any change after the spec sheet is confirmed must include:

- what changes

- cost impact (increase/decrease)

- lead time impact (+days)

- who approves

- effective date

If this is not done, both sides will remember different versions of the deal.

15) Red Flags and Green Flags in Supplier Communication

Green flags

- replies reference your numbered questions

- supplier sends checklists and timeline without being pushed

- supplier offers serial number tracking and real-time photos

- clear explanation when something is not possible

- consistent documentation (same model name everywhere)

Red flags

- “Yes yes no problem” for everything, no details

- avoids sending nameplate photos or certificate details

- pushes for full payment but resists inspection

- lead time keeps changing with vague reasons

- refuses to confirm specs by email (only wants chat)

16) Practical Templates: Messages, Meeting Agenda, and Order Checklist

These are copy-and-paste friendly, and they keep things smooth.

Template A: First serious inquiry (B2B)

Subject: Mini Excavator Inquiry – Configuration + Lead Time + Compliance

Message:

Hello, please quote for mini excavator model: (operating weight class).

- Engine brand/model and emission level:

- Hydraulic pump type and rated flow:

- Main valve brand/model (if available):

- Aux hydraulic lines: single/double + flow requirement:

- Cab/canopy, heater/AC:

- Attachments list (bucket width, quick coupler type, breaker piping):

- Track width and rubber/steel:

- Lead time based on deposit + final spec confirmation:

- What pre-shipment tests and inspection report can be provided?

- Certificates available for this exact model: (CE / other)

Please reply with a configuration sheet and photos/videos of the same model running.

Template B: Daily questions bundle (chat)

Today’s questions (PO: ___)

- Confirm decal proof is approved? (Yes/No)

- Engine nameplate photo available today? (Yes/No)

- Current production stage: (welding/painting/assembly/testing/packing)

- Any risk to schedule? If yes, how many days and why?

- Please send 3 photos: undercarriage / hose routing / full machine

Template C: Pre-shipment proof request

Before packing, please provide:

- serial number plate photo

- engine nameplate photo

- 2-minute running video (cold start + travel + swing)

- leak check photos (pump area + valve area + cylinders)

- packing photos (inside + sealing)

Mini Excavator Order Checklist (simple)

- signed configuration sheet (Layer 1/2/3)

- approved decal + paint proof

- confirmed timeline (with start date definition)

- inspection plan (who/when/what standard)

- certificate requirements written in contract

- packaging standard written

- spare parts list confirmed

- shipping term (Incoterm) confirmed

- change order process agreed

- final photo/video proof list agreed

FAQ

1) Is WeChat necessary when dealing with Chinese excavator suppliers?

It’s not mandatory, but it speeds things up a lot. The safest method is: use chat for fast coordination, then confirm important decisions by email.

2) How can misunderstandings be reduced if English is not perfect on the supplier side?

Use short sentences, numbered questions, photos, drawings, and simple “Confirmed / Not confirmed / Need cost / Need days” replies. Also use videos for anything visual.

3) What’s the best way to confirm the excavator configuration?

A signed spec sheet with three layers: non-negotiables, options, and acceptance standards. This prevents “same words, different meanings.”

4) How can certificate fraud risk be lowered?

Ask for certificate number + issuing body, high-resolution scans, and nameplate photos that match model/serial. Put compliance requirements in writing before payment.

5) What’s the most common reason shipments get delayed?

Unclear start date (deposit vs spec confirmation), missing custom decal approval, component shortages, and vessel booking delays. A phase-based timeline helps.

6) Should a third-party inspection always be used?

For first orders or large batches, yes, it’s smart. But inspection must be directed with a checklist—otherwise it becomes a “photos only” exercise.

7) How can a buyer negotiate price without harming quality?

Instead of forcing a deep price cut, negotiate value upgrades that reduce warranty risk (packing, hose protection, test report, spare parts kit).

8) What makes a supplier “easy to work with” long-term?

Consistent documentation, clear timelines, real-time production proof, and a structured QC routine. Suppliers with mature export systems—like Nicosail—tend to communicate in a more standardized way, which lowers friction for overseas buyers.

Summary

Effective communication with Chinese small excavator suppliers is not about sending more messages—it’s about sending clear specs, clear checkpoints, and clear confirmation rules.

- Use email for anything that affects money, time, compliance, or final configuration.

- Use chat for speed, and video calls for visual alignment.

- Replace vague words with measurable specs and acceptance standards.

- Lock lead time with a defined start date and phase timeline.

- Reduce risk using serial number proof, nameplate photos, and inspection checkpoints.

- Treat certificates, packing, and logistics terms as “must-define,” not “assume.”

Do these consistently, and the supplier relationship becomes calmer, faster, and far more predictable—exactly what buyers, distributors, and importers need to build a reliable mini excavator business.